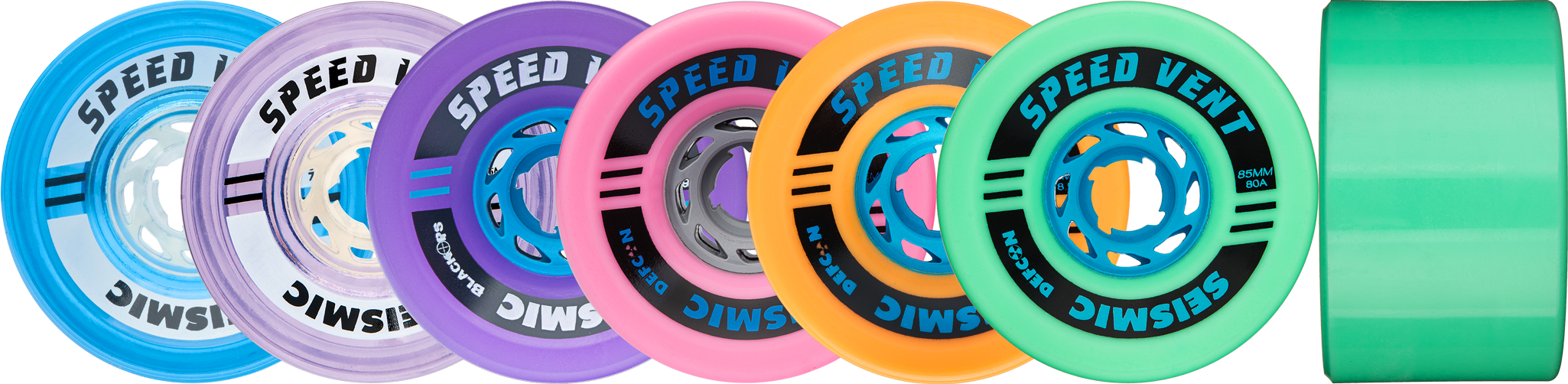

85mm tall x 52mm wide SPEED VENT Wheels

Offset bearing seat • 49mm running surface • Radiused outside edge, chamfered inside edge

8.6 oz. each • Sold in sets of FOUR wheels

Available in THREE proprietary formulas –

BlackOps™: ultimate balance of speed and grip • extreme traction fresh • buttery and smooth broken-in • comfortable and predictable

Defcon™: Guinness WR speed • directional slide • long-lasting grip • slow, consistent wear

Premium Clear™: the best beautiful clear urethane on the market • smooth, fast, and grippy

The very fastest wheel on the planet – used to set multiple World Speed Records – including Pete Connolly’s blistering mark of 91.17 mph / 146.73 kph (Sept. 16, 2017 at The Top Speed Challenge in Quebec, Canada); and Mischo Erban’s Official IGSA standup record of 80.83 mph / 130.08 kph (Sept. 30, 2010 in northern Colorado).

The 85mm by 52mm Seismic Speed Vent is molded around our proprietary Energy Conversion (EC) hub – the first tall, wide hub seen in longboarding and still second-to-none. The 85mm tire provides downhill roll speed, while the weight-saving hub adds the quickness and agility of a smaller wheel, as well as enhanced rebound. Combined with lips designed for pure grip, the Speed Vent stands in a class by itself.

Brandon –

I am definitely a recreational longboarder and relatively new to longboarding, but these wheels are installed on the second longboard I have built now, so I do have something to compare them to.

Clear blue 75A is the durometer I purchased in this wheel, along with the Tekton 6-Ball (red) bearings. Compared to the first board I built, these wheels and bearings are so much faster! The large diameter is nice for rolling over irregularities on riding surfaces, and the large diameter does not appear to slow them down at all. As an example, just sitting on the board with one of my other kids rolling down a hill, I will accelerate away from my son on the other board, which has 77mm wheels on it and freshly greased bearings. In comparison between the two boards, the one with the Seismic wheels and Tekton bearings feels like it is a powered board, no joke.

These are beautiful wheels, and I love how the sun shines through them. Overall quality is excellent and they have very little runout. While I am just a casual rider and have never done any slides or any aggressive type of riding, I will say they have a lot of grip while cornering.

I doubt I will ever wear out these wheels with the type of riding I do, but if I ever need to replace them I would without hesitation get another set of Seismic wheels!

Morgan Ewing –

I do some downhill but my main thing is long distance purpling. Last summer I had the chance to ride most of the best downhill and free ride wheels on the market. Some of them were good but these speed vent 85’s are truly amazing. Today I opened the box, popped the bearings in….and then rode for three and a half hours. I don’t think I put my foot on the ground once. They roll and roll and roll.

Alcuin Hipwell –

I am not a longboarder. I am an old school skater who used a 30×10 Alva deck with Tracker trucks, angled risers and a variety of 60-70mm wheels for everything, including Alvas, G&S YoYos, A series 70mm blue Kryptonics and B series 70mm red Kryptonics.

I now have a 30.5×10.25 deck with RKP trucks (96A Venom bushings on the rear, 90A Venom on the front), angled risers and either 75mm reissue red 78A Kryptonics or 85mm 77A Bubblegum DefCon Speed Vents for everything (I have 4 other sets of 60-70mm wheels but they don’t really compare and have only been ridden twice each). I suppose I am into LDP and a bit of DH these days, in the modern parlance. I haven’t fully broken the bearings nor the Speed Vents in yet but they already have a 5-10% advantage over the Kryptonics. Since I am not a slider, I am kind of wishing I had bought the clear blues instead (see Brandon’s review) but that’s a project for next year.

I cannot fault the increased speed of the DefCon 77A Speed Vents over the rough terrain of my local streets nor the fact that the core makes them the same weight or lighter than my 75mm wheels. Would I buy another set if I wear these out? Certainly. Am I also going to buy a set of 75A Clear Blues, just in case they are even better for what I want? Based on the DefCon 77A, absolutely!

Alcuin Hipwell –

PK. Follow up. At a cost of £160 (from eBay in France), I now have a set of 75A yellow Kryptonics. They beat the DefCon 77A Speed Vents hands down. They also beat their red Kryptonics equivalents even more. They are amazing! But we are talking about 8 year old, discontinued, limited edition, super rare wheels currently on eBay (US) for $325.00.

I still intend to get a set of 85mm 75A Clear Blues for comparison because I have a feeling that Brandon’s review may just be the tip of the iceberg about those wheels.

Jesper –

Many years ago i found my perfect ldp setup using Tekton ceramics together with Speedvents 79A front and 75A back on a Illuminati 28 with GBomb DD and Don’t trip Poppys angled in 69° front and 0° back.

youtu.be/whE1GOi1cyA 😎