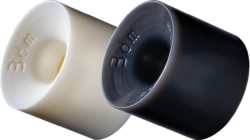

73mm tall x 56mm wide SPEED VENT Wheels

55mm running surface • Offset bearing seat • Square outside edge, beveled inside edge

6.1 oz. each • Sold in sets of FOUR wheels

Poured in Defcon™ urethane: Guinness WR speed • directional slide • long-lasting grip • slow, consistent wear

The 73mm by 56mm Seismic Speed Vent is molded around our proprietary weight-saving Energy Conversion (EC) hub – the first tall, wide hub seen in longboarding and still second-to-none. The 73mm diameter gives it the roll speed of a larger wheel, while the weight-saving hub adds the quickness and agility of a smaller wheel, as well as enhanced rebound. Combined with lips designed for pure grip, the Speed Vent stands in a class by itself.

Carlos Molesachi –

I love these wheels I actually got the bubble gum for the back and the mints for the front on my slalom board. I won the short course and placed second on the long course at the pump station Race in the amateur division on these. the dude who took first was riding the bubble gums on the back and the mangoes on the front so these are some really good Wheels in my opinion.