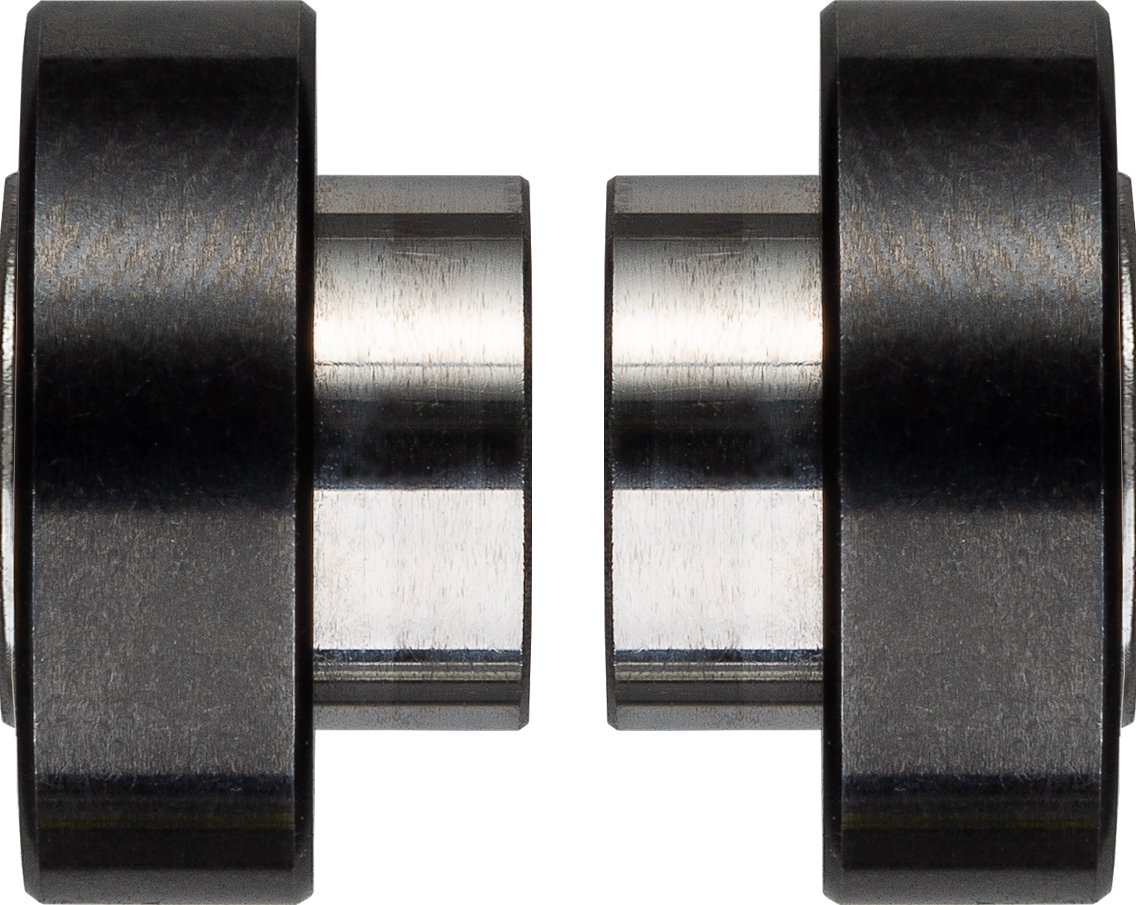

Fullspin® 10MM Steel XT™ Bearings with High-Precision Built-In Spacer System

Next-generation skate bearing tech – more speed, better handling, longer life!

ONLY for extra-thick 10mm axles. Will not fit standard 8mm axles.

We spent over two years nerding out with a crack team of American engineers from one of the biggest and best bearing factories in the world, to raise the bar on bearing tech yet again! Roll tighter, truer, faster, and smarter on Fullspin: the absolute best skate bearings in the entire history of skate bearings!

THE BASICS (Scroll down for more in-depth technical info.)

10MM system – Fits thicker 10mm axles only.

Premium Steel balls – Superior Grade G10 balls spin truer with less friction inside bearings.

Exceptionally tight, consistent assembly and raceway tolerances – Significantly less internal play, friction, wear, and noise. Superior speed, handling, and durability.

Extra-tough steel – Raceways hold strictest curvature and finest surface finish – and bearings stay tight and fast – for far longer. Stiffer outer rings resist flexing, spin truer and faster, and keep seals from popping off on extreme impacts. Premium black oxide surface treatment adds exceptional corrosion resistance.

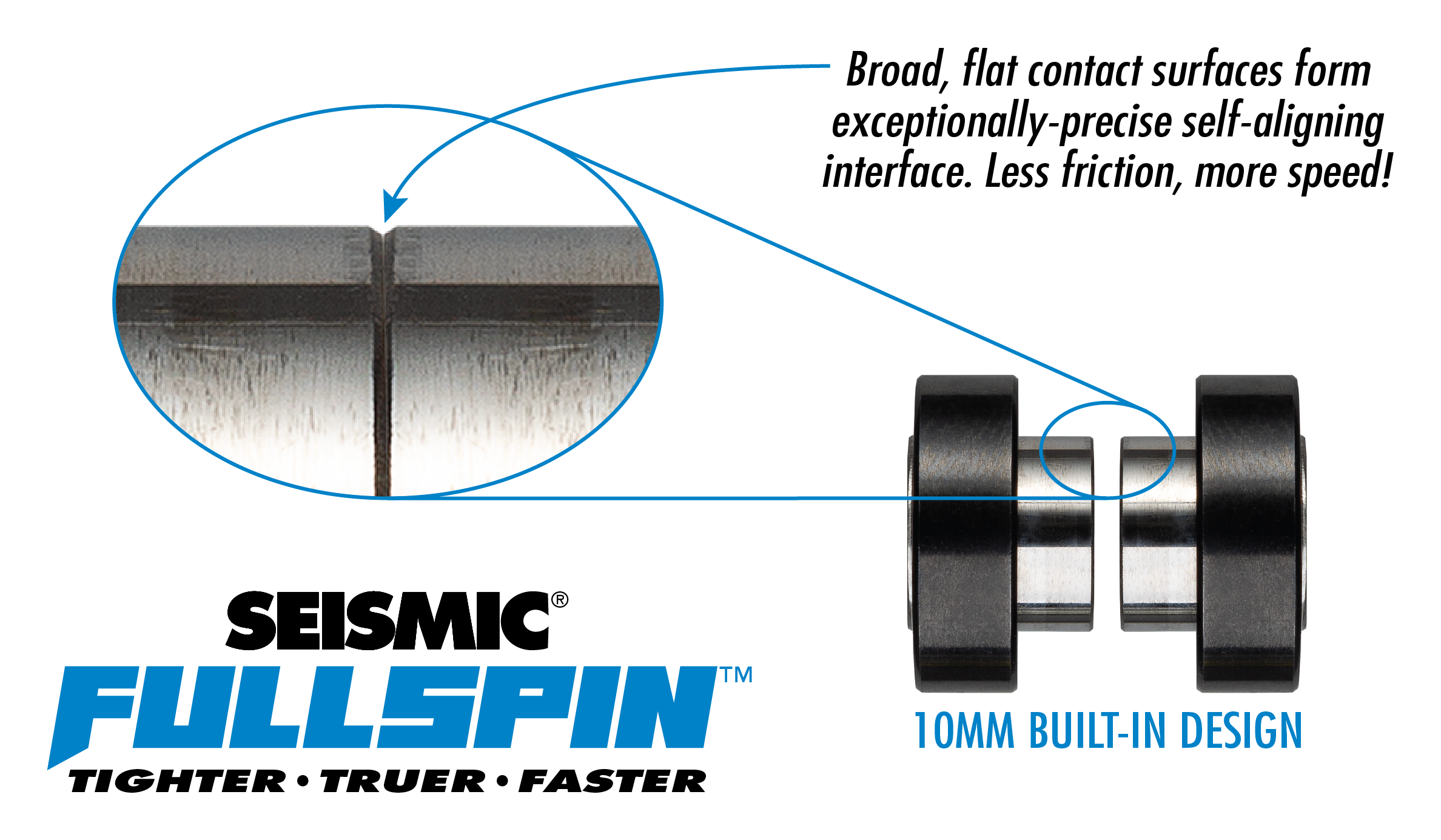

State-of-the-art Built-In spacing / alignment system – Integral half-spacers with smarter, stricter dimensional specs square up inside wheels with outstanding precision and stability. System levels and steadies all working components of seated bearings to unlock truly exceptional paired performance. Synergizes with all advanced features in individual bearings to maintain extremely consistent wheel contact and grip; support highly predictable slide performance; and noticeably extend both wheel and bearing life.

High-end lubricant – Formulated for peak performance under real-world skating stresses (not max free-spin time).

Labyrinth-style outer seals – Edges of seals slot inside V-shaped grooves for maximum resistance to dust and debris.

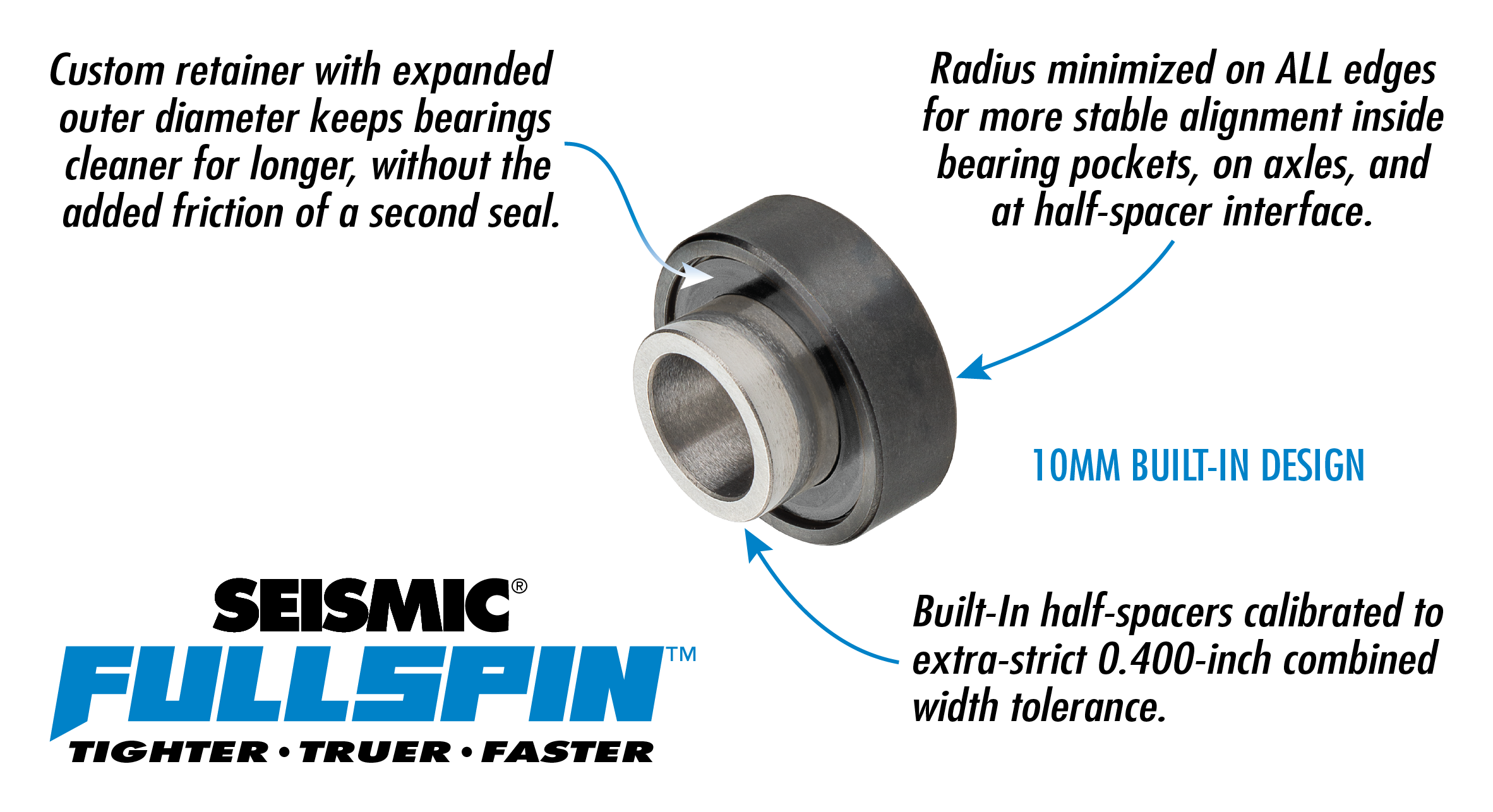

Next-level anti-contaminant ball retainers – Expanded outer diameter slots into groove in outer ring just like a second seal, to form a unique integral barrier against dirt and grime.

Fits thicker 10mm axles only. Nine-ball assembly custom-built with 7mm-wide rings for superior fit and stability inside standard wheel pockets. (Ordinary 10mm bearings are only 6mm wide.)

Superior concentricity, surface smoothness, strength, and durability. Manufactured to Grade G10 spec for truer, lower-friction ball spin inside bearings; less energy loss; more speed; and longer bearing life.

Compared to balls used in run-of-the-mill skate bearings, G10 specs are 60% – 80% tighter for concentricity (roundness), and 50% – 67% stricter for surface smoothness. (In simpler terms, twice as smooth as the finest cue ball, 10 times as smooth as a mirror finish.)

Manufacturing specifications for raceways and assembly are highly technical considerations, but absolutely mission-critical to overall bearing performance. Unlike other skate brands, Seismic fully committed to mastering the science and optimizing every last parameter.

See footnote below for the finer points.¹ The important takeaway is: Specs as tight and accurate as Fullspin’s are only possible at the very biggest, best-equipped, and most skillful factories in the world. The average small skate bearing producer can’t even come close.

The bottom line for rolling performance: Fullspin’s world-class factory tolerances result in significantly less internal play, friction, wear, and noise; and noticeably superior speed, handling, and durability!

¹ Radial clearance (gap between balls and raceway surfaces) held within a super tight and narrow range, with remarkably little deviation from the exact middle. Synergizes with extra-strict raceway curvature radius for outstandingly balanced load distribution across balls – a key determinant of overall bearing efficiency and toughness. Raceway surface finish up to 40% smoother than well-known brands. Superior tolerances for outer and inner ring concentricity (roundness), too.

Inner and outer rings precision-machined from superior steel with advanced heat treatment that fully optimizes metal’s crystalline microstructure. Raceways hold strictest curvature and finest surface finish – and bearings stay tight and fast – for far longer.

Outer rings are substantially stiffer than those seen on most other 10mm skate bearings (made with inferior steel). So they resist flexing, spin truer and faster, and keep seals from popping off on extreme impacts. Premium black oxide surface treatment adds exceptional corrosion resistance.

Radius reduced to bare minimum on all edges of both outer and inner rings – for fuller contact and more stable alignment inside bearing pockets of finer wheels; on axles of finer trucks; and at Built-In spacer interfaces. A Fullspin first!

Second only to Fullspin’s own patented Built-In system (seen in Steel and Ceramic XT models spec-ed for normal 8mm axles), the Fullspin 10mm Built-In alignment tech is state-of-the-art.

Integral half-spacers with smarter, stricter dimensional specs square up inside wheels with outstanding precision and stability. System corrects for off-spec axles and misaligned bearing seats.1 Levels and steadies all working components of seated bearings to unlock truly exceptional paired performance.

Synergizes with all advanced features in individual bearings to maintain extremely consistent wheel contact and grip; support highly predictable slide performance; and noticeably extend both wheel and bearing life

Built-in spacer lengths calibrated to extra-strict 0.400-inch combined width tolerance, to support highly accurate positioning of paired bearings inside finer wheels with well-engineered hubs.2

Radius reduced to bare minimum on all edges of extended inner rings, for fuller contact and more stable alignment at half-spacer interface.

Inner ring bore specs dialed to maintain exceptional straightness on finer 10mm axles. 0.5mm outside extension forms integral hanger / nut washer.

1 Common issues include micro-flaws in axle diameter, axle concentricity, axle straightness, bearing seat levelness, and bearing seat spacing.

2 Oversized built-in spacers seen in some well-known brands prevent at least one bearing in each wheel from fully seating. Wheels are then prone to lurching back-and-forth on the bearing stacks during hard turns and slides – causing inconsistent grip and slide behavior and prematurely-worn bearing pockets.

Packed with premium “high-RPM” light grease from Kyodo Japan. Formulated for peak performance under real-world skating stresses, not max free-spin time. Just press into your wheels and go!¹

Note: Free-spinning bearings or wheels by hand, under zero load, is not a meaningful measure of real-world performance (though none of us can resist free-spinning fresh new wheels and bearings). Fullspin’s advanced lubricant is designed to perform best when warmed up under the load of a human skater who’s rolling, turning, and sliding on real asphalt or concrete.²

¹ Do not clean – or add extra lubricant to – brand new Fullspin bearings. Wipe grime off outer seals whenever excess builds up. Clean and re-lube bearings only as needed, depending on how often and where you skate – more frequently if you ride through water, mud, dirt, or sand. Do not remove outer seals or disassemble in any way; just soak in isopropyl alcohol (70% solution or greater), rinse, and let dry. Avoid excessive cleaning, which increases risk of accidental damage to small internal components, as well as citrus-based cleaning solutions, which cause corrosion.

² Bearings may gain extended free-spin time if they’re under-lubricated, or lubricated with very thin oil, or assembled too loosely. But under real-world skating stresses, they won’t perform as well or hold up as long as high-quality bearings with tight assembly tolerances and appropriate lubricant – even though the latter may have a shorter free-spin. Most skating speed records have been set on bearings with modest free-spin. What matters is how bearings handle under the load of a human rider’s bodyweight – rolling, turning, and sliding on real asphalt or concrete.

Removable rubber-coated “no contact” steel seals with printed graphic. Edges of seals slot inside V-shaped grooves machined into both outer and inner rings. This “Labyrinth” interface maximizes resistance to dust and debris – which can only penetrate the bearing by navigating a twisting, maze-like path around seal edges.

Note: Seals protect bearings from environmental contaminants, which significantly accelerate wear. Properly-made “no contact” seals do not add friction. Brands that promote completely unsealed bearings just want you to wear yours out faster so they can sell you another set (that will also wear out prematurely).

Fullspin’s custom ball retainers keep bearings cleaner for longer, without the addition of a second seal. They feature an expanded outer diameter that slots into a groove in the outer ring just like a second seal – to form a unique integral barrier against dirt and grime.

Molded from an engineering-grade fiber-reinforced composite specifically formulated by the German producer for high stiffness and dimensional stability in bearing retainers and similar components.

We don’t bother with the ABEC rating system, which measures only the most superficial dimensional tolerances of the outer and inner rings – all of negligible relevance to real-world skating performance.

Other bearing brands frequently inflate or fabricate ABEC ratings to mislead the buying public. But even when accurately measured and reported, low-versus-high ABEC ratings have no direct correspondence with poor-versus excellent skating performance in the real world.

No wasteful, oversized metal tins or plastic cases – just a minimal recyclable cardboard box. Bearings and spacers wrapped inside VCI (“Volatile Corrosion Inhibitor”) paper – another Fullspin first! Adds superior protection against corrosion during transit and long-term storage of unopened packages.

Just superior performance through genuinely advanced, no-BS engineering; highest-quality materials and components; and highest-precision manufacturing.

100% FREE OF:

– Random bearing tech inappropriately adapted from other industries solely for the sake of novelty.

– High-sounding raceway coatings that interfere with optimal finishing and cause abrasive damage to ball surfaces.

– Flashy lubricant additives that accelerate wear not speed.

– Bombastic references to features and processes like the following (all totally ordinary and unexceptional at any decent, self-respecting skate bearing factory): deep-groove raceways with micro-channels, fine-polishing, fiber-reinforced nylon retainers, hand-inspection, and ultrasonic solvent washing.

Reviews

There are no reviews yet.